Personal

Description: Read about distinguished professor Gordon Wallaces' exciting address at the DeMANS Summer School on sustainable materials for additive manufacturing in Trinity College Dublin, spanning the entire breadth of research professor Wallace conducts from improved neurite growth using electrical stimulation to cartilage regeneration.

On the 25th of September 2024, Distinguished Professor Gordon Wallace of the University of Wollongong and the Intelligent Polymer Research Institute (IPRI) in Australia gave an address at the DeMANS Summer School on sustainable materials for additive manufacturing in Trinity College Dublin to chemistry and physics researchers. Wallace is a leading scientist in the field of electromaterials specifically focusing on the interface between nanotechnology and organic conductors, this places him as one of the scientific leaders in terms of sustainable materials and their use in clinical settings along with his peers at the Intelligent Polymer Research Institute.

Wallace began his talk titled ‘Bioengineered Solutions to Medical Challenges – The Discovery to Deployment Journey’ with an excerpt taken from his book titled ‘Organic Bionics’ published in 2012.

“The materials are usually not amenable to conventional processing and device fabrication methodologies, and ‘seeing’ how they perform in simulated operational environments (fluids) — with the need for spatial information (in the nanodomain) to provide topographical, chemical, mechanical and biological maps of surfaces – is challenging.” — Professor Graeme Clark, the University of Melbourne.

This quote was taken from the book's foreword, written by Australian Professor Graeme Clark, who specialises in Otolaryngology at the University of Melbourne. The quote does a good job at summarising the obstacles which befall any researcher attempting to brave the ever elusive field of bioengineering for medical applications, as well as assuring the audience that all of the research being presented during the address was the result of world class researchers putting in an extraordinary amount of time and energy to try and overcome the limitations of what is perceived to be non-standard materials for biomedical devices and to characterise novel materials with potential bionic applications.

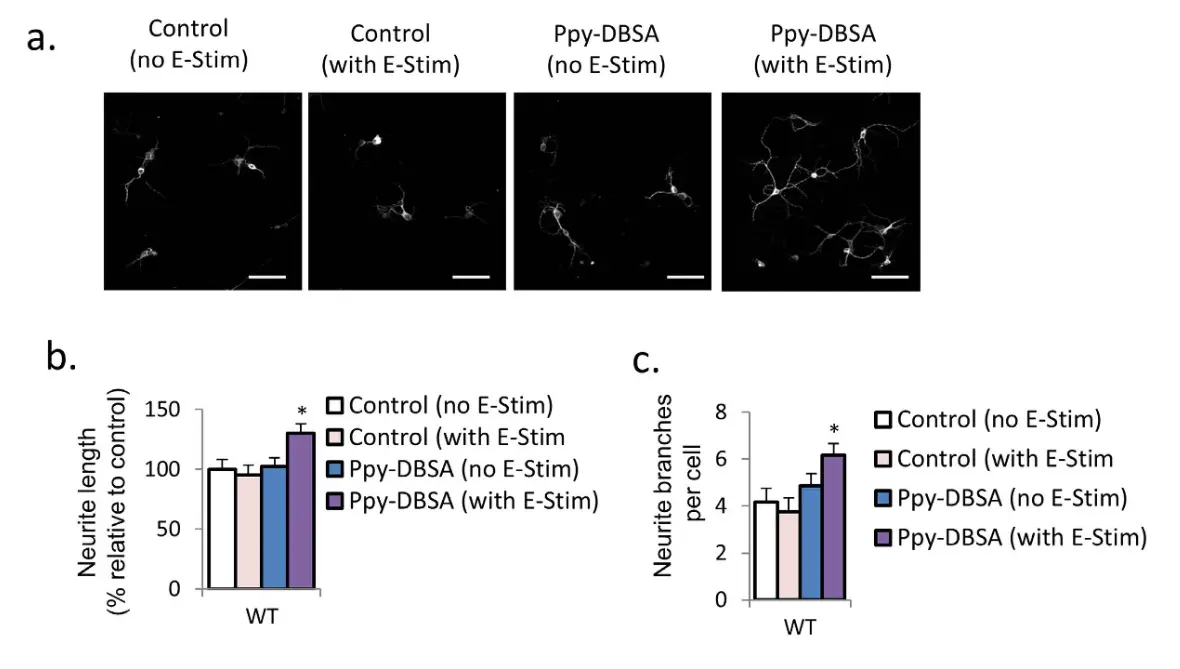

The first piece of novel research presented by Professor Wallace is the results of a paper published in Nature Scientific Reports titled “Electrical Stimulation Using Conductive Polymer Polypyrrole Counters Reduced Neurite Outgrowth of Primary Prefrontal Cortical Neurons from NRG1-KO and DISC1-LI Mice”. The paper explores the deficiencies in neurite growth implicated in psychiatric disorders such as schizophrenia - the paper used mice with NRG1-KO or DISC1-Locus impairment as representative examples of impaired neurite outgrowth of primary prefrontal cortical neurons. While NRG1-KO and DISC1-Locus exhibited reduced neurite length, number of neurite branches and reduced the synaptophysin and PSD95 protein and mRNA expression, this was not apparent for cultures on electroactive conductive polymer polypyrrole (Ppy). In his talk Professor Wallace stated how the neuron length was improved and the number of cells in the neurons dramatically improved. This paper opened up the possibility of using Ppy mediated electrical stimulation for treating neurodevelopmental diseases including, but not limited to schizophrenia.

Figure 1. Ppy-DBSA with electrical stimulation improved neurite growth in primary PFC neuronal cultures from wild-type mice. (a–c) Immunofluorescence with MAP2 reveals that Ppy-DBSA with electrical stimulation upregulates neurite length and the number of neurite branches in mice primary PFC neuronal cultures. Scale bar=50μm. Error bars indicate SEM. *p<0.05 vs control.

The cultures described above and in the paper published in scientific reports were electrically stimulated using a two-electrode setup with an auxiliary platinum mesh electrode placed onto the media at the top of each well with the Ppy coated Au-mylar surface acting as the working electrode. However the topic of electrical stimulation was a great segway to graphene. During his talk professor Wallace described two of graphene's distinct characteristics, the first is that it is totally organic, and the second is that it is highly conducting. Wallace then went on to describe the method by which graphene can be obtained, describing the process of mining the raw graphite from the earth and processing the material to turn it into useful structures. In 2022 alone 1.3 million tonnes of graphite was mined from the earth, this is an increase of 15% from the 1.1 million tonnes mined in 2021. In 2023 this number jumped to 1.6 million metric tonnes with China being the leading producer worldwide, About 70% of all graphite production is mined in China. In 2022 total production capacity of graphene was at 20,000 tonnes that's just 1.5% the production of graphite in the same year.

At this point in his address Professor Wallace emphasised the importance of sourcing high quality materials. Despite 1.3 million tonnes of graphite being mined in 2022 and only 20,000 tonnes of graphite being produced in the same year - not all of that 20,000 tonnes can be used for high quality material research. In fact the applicability of that graphene differs greatly in quality and flake size according to professor Wallace. This resulted in himself and his collaborators having to put in a lot of work in sourcing graphite to get as high a quality as possible.

It was at this point that Professor Wallace introduced another one of his papers around the material graphene. A paper published in Nature Nanotechnology titled ‘Processable aqueous dispersions of graphene nanosheets’. The paper describes how graphene sheets offer extraordinary electronic, thermal and mechanical properties - and how with this low-cost processing technique the production of large scale aqueous graphene dispersions is now a possibility. The paper showed that aqueous graphene dispersions were readily formed by controlled chemical conversion of GO Colloids without the need for either polymeric or surfactant stabilisers, through electrostatic stabilisation which is strongly dependent on pH. The paper concludes by stating the authors believe that the work will be a significant step forward to bringing graphene materials much closer to real-world applications. Professor Wallace then went on to give us an example of one of these real-world applications by describing the work done by a postdoc in his group involving being able to tie graphene fibres into a knot without affecting the electrical conductivity effects of the graphene. These electrical conductivity effects are extremely important as research shows that electrical stimulation of the vagus nerve can trigger immune response for certain diseases such as:

The idea of triggering an immune response along with this new found technique of being able to tie graphene fibres into a knot opened the possibility of super-flexible suture-like electrodes made of graphene (sutrodes). This work was explored by both Gordon Wallace and Dr Mario Romero-Ortega, Department head of Biomedical Engineering at the University of Arizona in the Nature Communications Biology paper published in 2021 titled ‘Platinized graphene fiber electrodes uncover direct spleen-vagus communication’. The paper posits that neuromodulation of the spleen inhibits the production of inflammatory cytokines and has substantial clinical applications while demonstrating that the type of terminal branch, and the specific electrical stimulation parameters used, can either increase or suppress the activity on the splenic fascicles, paving the way for a more selective and complete neuromodulation strategy for the spleen, and consequently, for the treatment of chronic inflammatory conditions.

Professor Wallace lamented that these concepts are still very far from clinical deployment due to it being hard to get reproducible performance and the need for sourcing to become regulated or else it is not suitable for medical application – Wallace went so far as to state that he did not believe these ideas would be deployed in his lifetime. These issues around medical deployment encouraged Wallace to explore 3D printing, as a way to overcome these challenges - with materials that are easier to regulate.

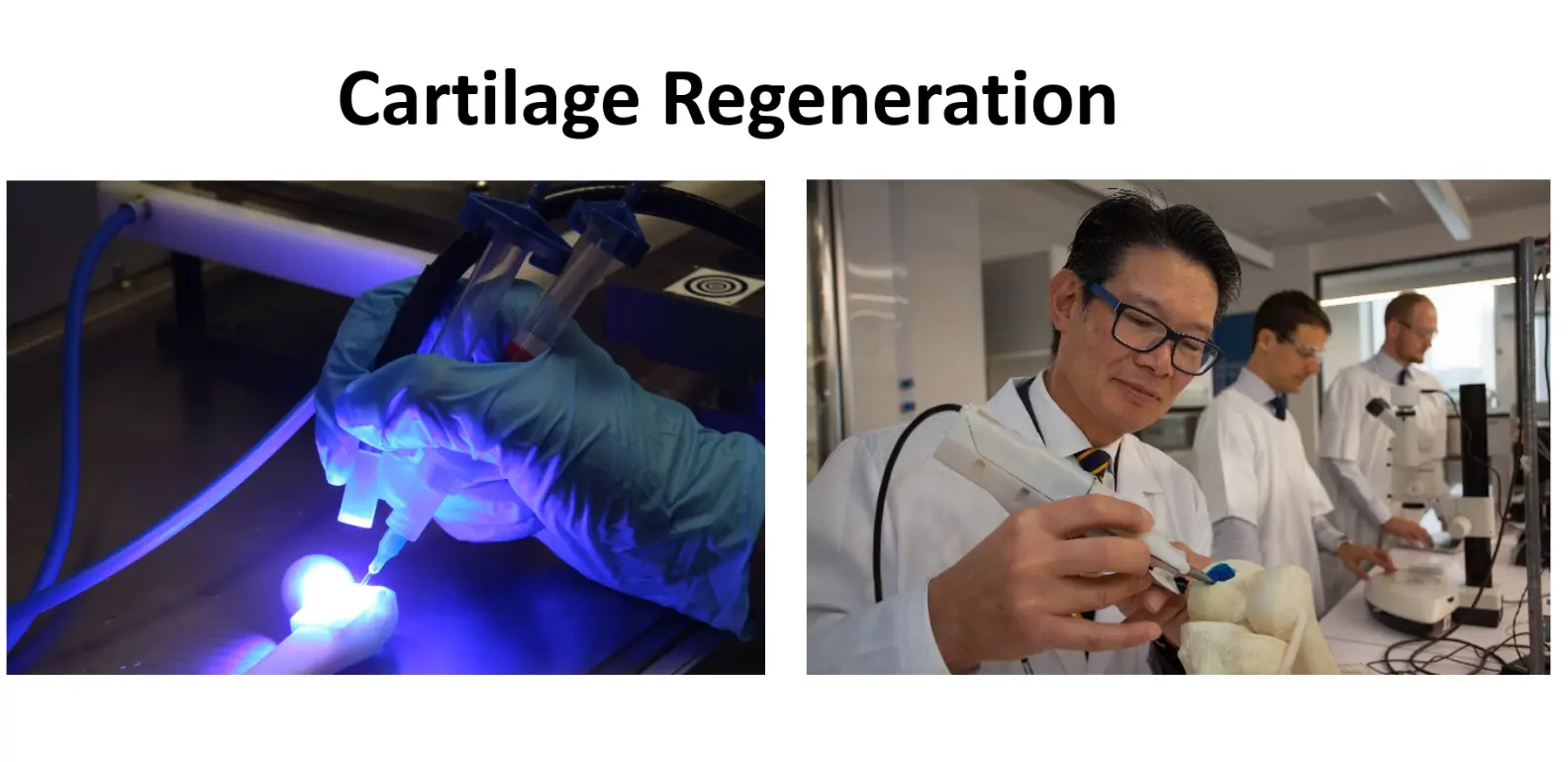

One of the main areas of interest for Wallace and his team of researchers regarding 3D printing is cartilage regeneration. Wallace described one of his papers published in PlosOne in 2014 which explores the idea of using infrapatellar fat pad adipose stem cells (IPFP-ASCs) in combination with 3D polymeric structures to engineer 3D tissues for cartilage repair. Professor Wallace clarified, when a question was raised about the sourcing of these stem cells, that the concept was planned from the beginning to collect the stem cells necessary for the cartilage repair from the patient themselves. Wallace went on to joke that the surgeons don’t like too much complexity added to their procedures and that their ideal version of a 3D printer would just be two buttons: on and off. If you want to deploy these types of machines in medical environments they have to be incredibly simple. Meanwhile - engineers' ideal printing would be to get rid of the surgeon and have a robotic arm do the printing.

Gordon finished this segment of his talk about cartilage regeneration sharing the news that the first human trial of this technique is planned for next year. Despite that seeming relatively quick - Wallace clarified that it has taken 10 years to get to this stage. Wallace didn’t attribute this 10 year challenge to working with the stem cells nor sourcing the materials but instead to sourcing the stem cells and separating them. It takes 8-weeks from the extraction of the stem cells from the knee to having usable cells, for surgery purposes this timeline needed to be reduced to just a matter of hours.

Finally, Wallace touched on some of his research around the topic of bioengineering the cornea. This research is being done in collaboration with Prof Gerard Sutton (eye surgeon from the Vision Eye Institute and University of Sydney). The human cornea consists primarily of three layers between these layers rests the corneal stroma that makes up 90% of the corneal thickness, individual layers composed of fibres of collagen, orthogonally arranged, so that the fiberals run at right angles. This structure gives the cornea its biological and mechanical properties that would need to be reproduced if one wanted to bioengineer the cornea. In their 3D assembly method Wallace and team induced an electrical field causing the collagen fiberals to come together in an aligned manner making it possible to pick up with tweezers. If the fiberals are not aligned correctly the collagen lacks this mechanical structure. Bio-glue is then used to put all of these layers together to produce an engineered cornea. Wallace revealed during his talk that he had been funded to make a biomanufacturing line for these bioengineered corneas. Professor Gordon Wallace concluded his talk with an extremely exciting statistic, stating that these bioengineered corneas take cells from donated corneas and from a single donated cornea they can generate 30 engineered corneas. Today only 1 in 70 people on the waiting list are receiving cornea transplants.

A sincere thank you to Professor Gordon Wallace for taking the time to give this talk at the DeMANS summer school at Trinity College Dublin and for sharing his exciting research around bioengineered solutions to medical problems with ambitious PhD and postdocs whos projects all contain a common theme of sustainable materials for additive research.

Personal

Solid State Physics

Programming

Share this Article